Headgates, chutes and crowding pens don’t need to be expensive or elaborate.

The purpose of the Beef Quality Assurance program is ensuring the customer that beef producers are responsibly raising their cattle to produce beef that is safe, wholesome and tastes good.

Animal welfare is a key principle of BQA certification and is defined as providing the necessary care to protect the health and well-being of animals. Without proper working facilities, producers cannot properly care for sick or injured cattle, assist with calving difficulties, or prevent disease through routine vaccination.

Therefore, beef producers must have adequate working facilities not only to meet BQA certification, but also to demonstrate that they are responsible caretakers of cattle.

Fortunately, working facilities need not be too expensive or elaborate. Here are some guidelines on some of the minimum components of a cattle-working facility:

Headgate. The headgate is the most important part of the working facility. It should be sturdy, safe and easy to operate, and work smoothly and quietly.

There are two basic types of headgates: the self-catch type and scissors-stanchion.

The self-catch is easy to operate for one person; cattle work fast and exit easily. However, in cow-calf operations where cows are worked routinely, they soon become timid of getting caught, requiring an operator to pull the headgate closed.

In addition, self-catch headgates are inconvenient for working cows and young calves at the same time as the smaller calves will go through the headgate without catching their head.

The scissors-stanchion type has two halves that pivot at the bottom. It is simple and costs less, but it requires an operator to catch the animal. Cattle can get shoulder bruises, and they can get through without being caught.

Both types of headgates are available with either straight or curved stanchion bars. The straight-bar stanchion is very safe and will rarely choke an animal. The disadvantage is that animals can move their heads up and down unless a nose bar is used.

The curved-bar stanchion offers more control of the animal’s head, but it is more likely to cut off circulation. I have seen animals become unconscious in minutes due to lack of blood supply to the brain.

Working chute. The working chute holds cattle in a single file ready to enter the headgate.

As cattle instinctively follow each other, the chute should be long enough to hold at least three animals, preferably four to five. The biggest mistake producers make in designing a facility is not making the chute wide enough. It should be no wider than 32 inches, and for most cattle 1,600 pounds or less, 28 inches is ideal.

If the chute is curved it will help the cattle move easier. A chute with sloping sides will allow different sizes of cattle to be worked and still prevent turning. Solid sides up to 48 inches can ease cattle movement. If the entire chute is solid, then the cattle won’t see you and, therefore, will be difficult to move forward.

Crowding pen. The purpose of a crowding pen is to get cattle into the working chute single file and in the right direction. There are two main types: tub and bud box. The tub has a swinging gate that pushes behind the cattle to get them into the chute.

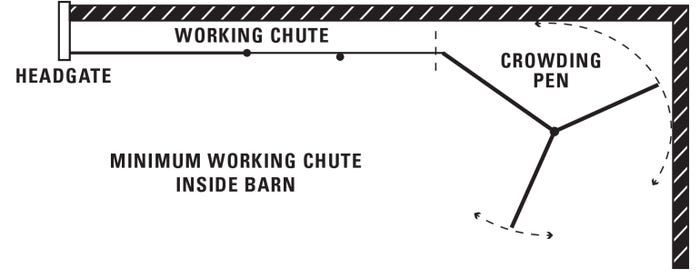

The graphic below shows an example, using the corner of a building. This design can also be free-standing. Forty-eight-inch-high solid sides and crowd gates help to avoid the cattle being distracted.

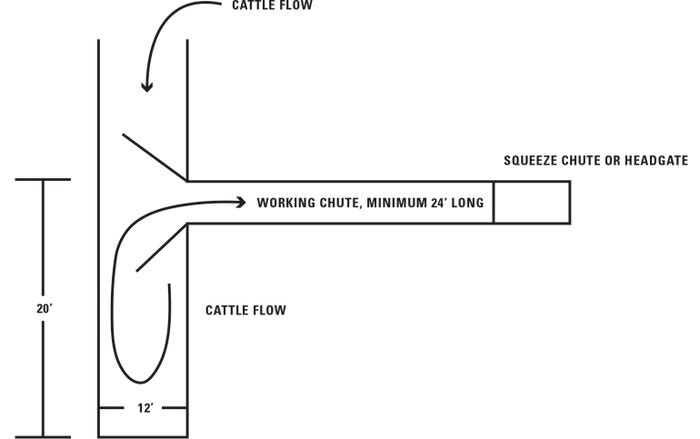

The second style of crowding pen is the bud box, developed by Bud Williams, pictured below. The system is based on the cattle’s instinct to go back from where they came from and to work around the handler. The advantage is that it is relatively inexpensive and portable. The disadvantage is that the handler must be in the box with the cattle.

Additional components of a handling system are a squeeze chute, which contains the headgate; scales; cut-off gates; anti-back devices; palpation cage; and load-out alleys.

For the value of two feeder calves, a system can be built that is safe for the cattle and the handler. This should not be optional on any beef operation.

For more information on BQA, contact Nancy Glazier, Extension educator and co-BQA chairwoman, at [email protected], or contact your local Cooperative Extension office.

Baker is a senior Extension associate in the Cornell Department of Animal Science.

About the Author(s)

You May Also Like