The amount of retail cuts coming from a finished calf depends on5 things. Paul Beck gives us a look at what those things are.

April 29, 2021

Rural landowners are often interested in raising livestock to slaughter for personal consumption, local marketing or for normal commodity markets. There are several options producers can use to finish cattle, ranging from finishing completely on forages to conventional drylot programs using high concentrate diets. Hybrid systems have been studied as an alternative to high-concentrate total mixed rations fed in confinement. These systems utilize the roughage supplied by pasture along with additional energy from supplemental concentrates. They may not meet the requirements to meet ‘grass-fed beef’ claims by the USDA, but do provide free-choice access to pasture.

An Alternative Finishing System

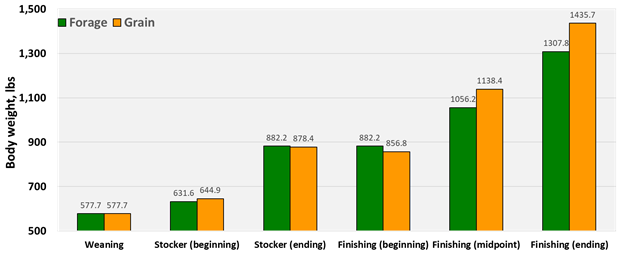

I conducted research with Jason Apple, a meat scientist currently at Texas A&M Kingsville, to compare conventional finishing at a High Plains feedyard to the hybrid ‘grain-on-grass’ system. In the first trial, calves from spring or fall calving herds were either sent to a Texas Panhandle feedyard for finishing as yearlings following a stocker program or kept at the home operation and supplemented with 1% of bodyweight per head per day with a grain/grain byproduct supplement until slaughter. Steers finished conventionally in confinement gained 4.4 lbs/day while steers fed concentrate supplement on pasture gained 2.5 lbs/day. Although the finishing period on pasture was 30 days longer on the average, steers finished in the conventional feedlot were 128 pounds heavier at slaughter and dressing percentage was higher 62.5% vs 60.6% for Conventional and Pasture, respectively). Conventionally finished cattle were 86% Choice while pasture finished were 78% Select quality grade.

Figure 1. Effect of finishing on pasture (Forage) with 1% of bodyweight concentrate supplement daily or conventional finishing (Grain) on bodyweight of steers.

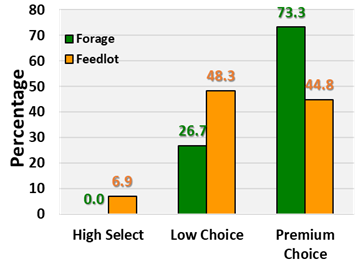

In the next trial, 60 calves were either finished in conventional Texas Panhandle feedyard or were kept on pasture with a grain/grain byproduct concentrate supplement fed at 1.5% of bodyweight daily. Steers finished on pasture with supplement gained 3.6 lbs per day (vs 4 lbs/day for conventional) and were fed 40 days longer than conventional steers, but were again still 40 pounds lighter at slaughter. But, hot carcass weights (836 for pasture vs 854 for conventional) were not as impacted as in the previous study, fat thickness was similar for the 2 treatments (0.62 inches for pasture vs 0.52 for conventionally finished) and dressing percentage was likewise similar (63% for pasture and 62.5% for conventional). In this experiment the cattle finished on pasture with supplement were 100% Choice with 73% being Premium Choice, while the Conventional steers were 93% Choice with 45% being Premium Choice. This research indicates that acceptable carcass performance can be obtained with limited energy supplementation on pasture.

Figure 2. Effect of finishing on pasture (Forage) with 1.5% of bodyweight concentrate supplement daily or conventional finishing (Grain) on carcass quality grade.

There are several items that producers should be aware of and be able to communicate to consumers if selling directly.

The amount of retail cuts coming from a finished calf depends on the frame, muscling, skeletal structure, fat cover, and gut fill.

The conversion of live animal depends on dressing percent (the amount of carcass per pound of shrunk live weight), in grain finished calves this ranges from 58% (usually dairy calves) to 66% (highly finished heavyweight beef steers), but in forage finished calves this can be much lower, usually due to gut fill and lower fat cover.

A rule of thumb is on a well finished calf (0.6 inch of backfat at the 12th rib), you can expect red meat yield to be about 50% of the shrunk live weight of the animal (empty of gut fill).

A tool to estimate red meat yield from a carcass is the Beef Cutout Calculator (http://beefcutoutcalculator.agsci.colostate.edu/). The user must be aware that this is based on the average grain finished carcasses, and differences in finishing system will affect your results.

In summary, finishing cattle on farm can be an economical enterprise to add value to cattle. Finishing systems are not one size fits all and should be tailored to fit the producer’s production goals, target market, and management expertise. For more information about on-farm finishing programs look at our new Fact Sheet AFS-3303 Finishing Beef Cattle On the Farm

https://extension.okstate.edu/fact-sheets/finishing-beef-cattle-on-the-farm.html

Source: Oklahoma State University, which is solely responsible for the information provided and is wholly owned by the source. Informa Business Media and all its subsidiaries are not responsible for any of the content contained in this information asset.

You May Also Like