Supporting Animal Welfare Tools and Technologies

Ensuring that cattle are well-cared for and protecting high-quality animal health are two of a veterinarian’s highest priorities. Understanding how impaired mobility negatively affects cattle welfare and what factors to consider in order to mitigate these challenges is critical to protecting the welfare of fed cattle presented for harvest.

September 18, 2017

Sponsored Content

As caretakers of animals, veterinarians seek continuous improvement with regards to animal welfare. The optimization of cattle health and comfort helps drive productivity and contributes to more sustainable beef production. Elanco has invested in multiple cattle mobility-focused studies to analyze data, identify opportunities and measure progress toward improved animal welfare.

Elanco technical consultants Michelle Calvo-Lorenzo, M.S., Ph.D., and Jacob Hagenmaier, D.V.M., Ph.D., have been deeply involved in research evaluating the impacts of handling techniques on the physiological responses of fed cattle during transportation to packing plants. They were also involved in developing and implementing a mobility scoring program for evaluating cattle upon presentation for harvest.

“We now have a better understanding of the factors that affect cattle mobility, with a specific focus on the behavioral and physiological responses that fed cattle present when exposed to different management practices such as handling and transportation,” Calvo-Lorenzo stated. “We are beginning to comprehend what fed cattle are coping with and what mitigation strategies can be used to help prevent impaired mobility.”

Development of a new mobility scoring program

Elanco developed a cattle mobility scoring program to be implemented as a benchmark welfare tool for the industry. Heightened awareness about mobility not related to obvious signs of musculoskeletal injuries or disease in fed cattle, in addition to identifying a knowledge gap about the proportion of cattle that are presented for harvest with impaired mobility, contributed to that decision.

“We needed to determine the prevalence of abnormal mobility and factors related to the disease state to begin finding solutions,” Calvo-Lorenzo said. “Severely impaired mobility is a rare and sporadic issue, so Elanco built a program targeted at measuring the occurrence of this condition industry-wide and focused research efforts based on data and analytic outcomes.”

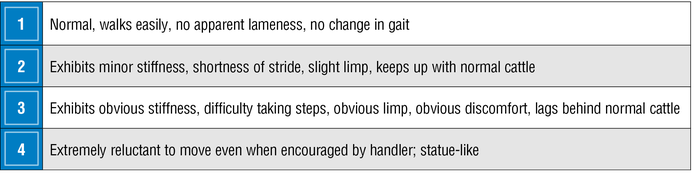

Utilizing the mobility scoring system developed by the North American Meat Institute (NAMI),1,2 Elanco developed a Cattle Mobility Assessment program that measures and defines the state of mobility that fed cattle exhibit at packing plants. The program incorporates the NAMI mobility scoring system, which has been implemented industry-wide and is usable by any trained observer at any point during the production system.

NAMI Mobility Scoring System1,2

NAMI has a training video available online for cattle caretakers to train themselves or their employees on the scoring system. “One of the best things about this scoring system is that it can be used by anyone who has been adequately trained and can be incorporated as part of a facility’s or company’s overall cattle welfare program,” said Calvo-Lorenzo. “Veterinarians can train themselves to capture this mobility data and determine mobility trends across their customers’ herds or feedlots.”

Physiological responses to handling and transportation

In addition to the mobility scoring program, Elanco has also collaborated with a team of investigators at Kansas State University to develop a research program designed to identify contributing factors of impaired cattle mobility. The first study, conducted in 2014,3 evaluated the physiological responses of cattle when they were exposed to different handling techniques immediately before shipment for harvest. All cattle in the study were fed Optaflexx®.

“Although a fair amount of research has been reported that defines the negative implications associated with improper handling, that research is relatively old and did not follow the cattle to the packing plant,” Hagenmaier stated. “Therefore, we felt the need to revisit this question in contemporary cattle to not only follow the cattle through the marketing channel, but also because factors such as slaughter weight, genetics and the use of technologies have changed dramatically over the last few decades. A logical starting point was to study the physiological responses in cattle that had different handling techniques applied, such as cattle that were walked with a use of a lead rider versus cattle that were trotted without a lead rider,” said Hagenmaier.

Although several measurements were obtained throughout the study, one highlight of the research was the comparison of biochemical markers of fatigue and stress. According to Hagenmaier, the results of this study confirm that when handled improperly, fed cattle can quickly develop metabolic acidosis.

“When comparing fatigued and non-fatigued cattle after handling at the feedyard, the cattle that became fatigued had greater blood lactate concentrations and lower blood pH compared to their non-fatigued cohorts,” said Hagenmaier. “This suggests that metabolic acidosis is a predisposing factor for fatigued cattle.”

Building knowledge with two-phase research

A second study was conducted in 20154 that utilized a similar handling model, but a key differentiator in this study was the administration of Optaflexx as a second treatment level. This study consisted of two phases. Phase 1 sought to evaluate the effect of feeding Optaflexx for 28 days on growth performance; phase 2 evaluated the effect of Optaflexx and handling techniques on cattle mobility and blood parameters on the day of shipment for harvest.

According to Hagenmaier, the effect of Optaflexx on growth performance was as expected. “The cattle fed Optaflexx had hot carcass weights that were over 15 pounds greater than for cattle not fed the product, which was important because it established their response to the feed additive and set the stage for the second phase of the study.”

A multitude of variables similar to the 2014 study3 were measured during the handling phase. Handling without a lead rider resulted in cattle developing metabolic acidosis, regardless of whether or not they had been fed Optaflexx. Additionally, mobility scores were not different between cattle fed Optaflexx when they were scored at the feedlot or after 6 hours of lairage at the packing plant.

Another point to consider were the baseline blood variables. “While we observed a lack of differences in relation to the mobility of cattle based on whether or not they were fed Optaflexx, it is also noteworthy that the carcass gain was achieved without any alteration of the physiological status of the cattle based on the baseline levels of numerous blood variables,” Hagenmaier emphasized.

In addition to low-stress handling practices, producers can consider the following practices to help mitigate the incidence of abnormal mobility or cattle fatigue:

Stage pens at re-implanting to position heavy cattle near load-out facilities to reduce the distance that cattle have to walk on the day of shipment for harvest

Identify days when extreme heat is expected and avoid performing weigh-outs during times of high temperatures

Coordinate timing of pick-up with packers to minimize the time cattle are required to stand in load-out areas

Use a lead rider to handle cattle to prevent cattle from running down drovers’ alleys

Protecting technologies for the future

As a continuation of their mobility research program, Elanco is currently involved in two additional research studies to further evaluate the prevalence and etiology of impaired mobility in fed cattle. The findings of the on-going and completed studies, alongside the continuous monitoring of mobility in the field by Elanco’s Cattle Mobility Assessment program, will help equip beef industry professionals when implementing management strategies to ensure the highest level of animal welfare while cattle are being transported for harvest.

“Animal caretakers need to be able to optimize the way they care for their animals and select the management strategies of their choice based on the science available,” Calvo-Lorenzo emphasized. “Regarding cattle mobility, we know veterinarians, producers and packers are working every day to do the right thing for their cattle and are continuously seeking validated tools to help them optimize welfare and track progress. We applaud and support these efforts, and are working to help them understand the science of mobility and enable the industry for success.”

If you have questions about training on the NAMI scoring system or the results of these studies, please reach out to your Elanco sales representative or technical consultant.

The label contains complete use information, including cautions and warnings. Always read, understand and follow the label and use directions.

Caution: Not for animals intended for breeding.

Optaflexx: Complete feed

For increased rate of weight gain and improved feed efficiency in cattle fed in confinement for slaughter: Feed 8.2 to 24.6 g/ton of ractopamine hydrochloride (90% DM basis) continuously in a complete feed to provide 70 to 430 mg/hd/d for the last 28 to 42 days on feed.

For increased rate of weight gain, improved feed efficiency and increased carcass leanness in cattle fed in confinement for slaughter: Feed 9.8 to 24.6 g/ton of ractopamine hydrochloride (90% DM basis) continuously in a complete feed to provide 90 to 430 mg/hd/d for the last 28 to 42 days on feed.

Optaflexx: Top dress

For increased rate of weight gain and improved feed efficiency in cattle fed in confinement for slaughter: Feed 70 to 400 mg/hd/d of ractopamine hydrochloride (90% DM basis) continuously in a minimum of 1.0 lb/hd/d top dress Type C medicated feed (maximum 800 g/ton ractopamine hydrochloride) during the last 28 to 42 days on feed.

1North American Meat Institute. (2015, June 19). Mobility Scoring for Cattle. https://www.youtube.com/watch?v=QlslfHCvkpg.

2Edwards-Callaway, L.N., Calvo-Lorenzo, M. S., et al. (2017). Mobility scoring of finished cattle. Vet Clin Food Anim, 33(2017), 235-250.

3Hagenmaier, J.A., Reinhardt, C.D., et al. (2017). Effect of handling intensity at the time of transport for slaughter on physiological response and carcass characteristics in beef cattle fed ractopamine hydrochloride. Journal of Animal Science, 95(5), 1963-1976.

4Hagenmaier, J.A., Reinhardt, C.D., et al. (2017). Effects of ractopamine hydrochloride on growth performance, carcass characteristics, and physiological response to different handling techniques. Journal of Animal Science, 95(5), 1977-1992.

Optaflexx, Elanco, Full Value Beef and the diagonal bar are trademarks of Eli Lilly and Company or its affiliates.

© 2017 Eli Lilly and Company or its affiliates.

fyfeed 8202-1

USBBUOPT00125

About the Author(s)

You May Also Like