It was 50 years ago that Gary Vermeer created that first large round baler. That one concept was the start of a new way to make feed, and solidified the future of the company.

January 6, 2021

There are many who may not know that Vermeer Mfg., existed before founder Gary Vermeer came up with the large round baler. "He worked on a lot of solutions including trenchers and stump grinders, he was always working to solve problems," says Mindi Vanden Bosch, Vermeer's granddaughter.

The story of the creation of a new idea can often be shrouded in myth, but for the round baler the Vermeer family has kept in touch with the truth of the story. More than 50 years ago the farm labor shortage was already causing problems. The difficulty of getting a crew to help make hay in a timely fashion and at an affordable price, challenged many.

A cow-calf operator friend of Vermeer's mentioned he was struggling with the labor required to put up hay. The producer said if he couldn't find a better way to make hay, he was going to get out of the cattle business.

That's when Gary Vermeer's farmer-inventor mind started to spin. The idea of a round bale wasn't new, there were small round balers on the market. But going bigger became the solution and offered a way to collect cattle feed in a bigger pile and created a one-person system for feed-making.

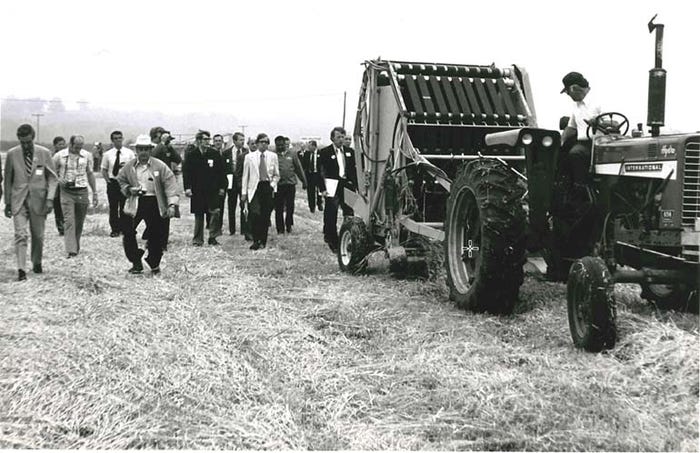

THE FOUNDER: Gary Vermeer was in business several years before he found fame with the first large round baler. His focus was inventing solutions to farm problems both for his operation and for others.

In fact, that first Vermeer round baler was a 706, that's right it made a seven-foot by six-foot bale. "When Gary built that machine, he was swinging for the fences right from the start," says Mark Core, executive vice president and chief marketing officer, Vermeer. "This was a big bale."

Vanden Bosch adds: "He was aiming to make a one-ton bale." She now directs the Forage Solutions division of Vermeer.

Celebrating a milestone

Honoring a machine's birthday isn't always top of the list for a journalist covering farm equipment, but the advent of the large round baler ushered in a totally new way to make feed. "You never saw a bale ring in the country before the large round bale," says Core.

But note that Vermeer doesn't make bale spears, bale rings, squeezers or a host of other equipment developed to make large-round bale handling easier. "Gary went with the round shape because he knew that would shed water, and leaving the bale in the field, it would maintain condition," notes Vanden Bosch.

This was before netwrap and bale wrappers, but 50 years ago the idea of having a good pile of feed, tied up and ready for cattle, made by one person, was a hot idea. "Gary worked to solve the big problem, which was making feed in a more convenient package," Core says. "He left the rest up to the market."

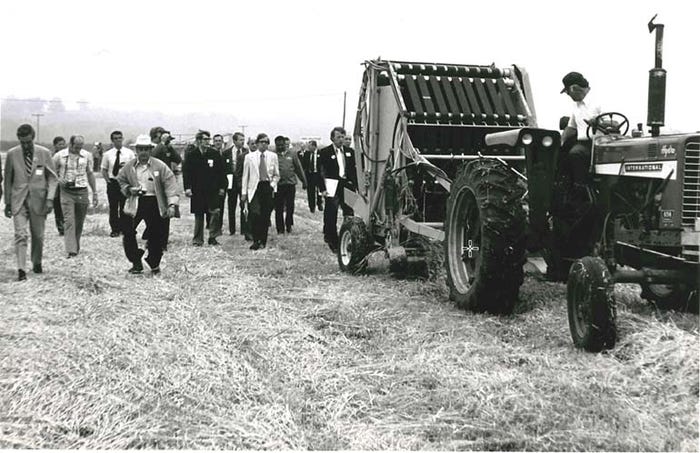

And boy did it get attention. Tom Bechman, long-time editor of Indiana Prairie Farmer, remembers the stir a Vermeer baler caused when it was demonstrated at local fairs. Farmers would make the trip to see this machine at work, and it drew large crowds.

What the baler innovation created

Vermeer Mfg. was founded in 1948, and Gary Vermeer focused on solving problems. He farmed land near the river in Pella, Iowa. It was bottom land that would flood, but he developed machines to manage that water. Vanden Bosch admits that her grandfather was frugal too.

"He once said given what that land cost he could take a flood, be forced to replant, and he was still ahead on his investment," she recalls. But that frugality led to machine innovations for trenching and other land work that Vermeer became known for, until that first round baler.

The culture of innovation, and problem solving continued and has grown. Over the years Vermeer has entered other businesses including higher end trenching equipment, and boring tools that today can be credited for making broadband technology available across the country. That's an area many farmers may not know about.

POPULAR DEMO: Gary Vermeer found it easy to draw a crowd baling with his new machine. Farmers followed along to watch the one-person approach to feed-making.

And service was also important for the company. Family members tell stories of Vermeer and his pilot's license. He was known to fly parts for broken machines to customers to get equipment working again. He would also make trips to talk with customers and learn about their operations.

"He was focused on the customer," Vanden Bosch says. "He was always working on ways to solve the customer's problem."

No easy 'in'

But as the company has grown what does that mean for the subsequent generations? "We have 72 shareholders across four generations," says Vanden Bosch. "They range in age from toddlers to adult children of Gary Vermeer."

She laughs as she tells about an 11-year-old Vermeer family member who made his mother stop on the road when he saw a customer using a competitive machine. The young shareholder asked the owner why he wasn't using Vermeer.

But being a Vermeer isn't a ticket to ride as a company employee. Vanden Bosch, whose mother – Mary Andringa, Gary Vermeer's daughter, recently retired as CEO of the company – couldn't just join corporate ranks.

Vanden Bosch explains that family members are required to leave, get their education and work elsewhere for a few years before considering a future with Vermeer. "I worked outside of the company for three years after I got my MBA," she recalls. "Then a position opened up at the company, and I applied."

Related: You can hear more about Gary Vermeer and he company he built in the latest episode of Around Farm Progress with Vanden Bosch and Core - check it out.

That's right, even the granddaughter of Gary Vermeer must go through the company's rigorous interview process. That was true for Vanden Bosch, and her brother Jason Andringa, who is the new CEO. "I worked in many departments across the company, as my brother did," says Vanden Bosch.

And the culture of innovation continues. Farmers are now flocking to see a new machine in the field – the ZR5-1200 self-propelled round baler. And they're buying too. Core notes that several Vermeer dealers have had success with the machine in the market as more farmers see what it can do.

"And that's something that the family and the company continues to foster," Core adds. "We have a group dedicated to developing new innovations for the industries we serve." Supported by Vermeer family funding, this division works independently to explore new ideas and Core says that group of engineers is looking into a wide range of innovations. That group developed the ZR5, and Core teases that more innovations are on the way.

It's easy for some companies to have success in one area and ride that for years until it's time to move on. But in agriculture, family-owned shortline companies that continue to innovate also keep building their businesses. For Vermeer and its 72 shareholders, the focus is on the future. But none forget innovations of the past that got the company where it is today.

To celebrate the 50th anniversary of Gary Vermeer's baler, the company has created as special website, learn more at vermeerbalers.com.

About the Author(s)

You May Also Like