June 5, 2017

Sponsored Content

Written By: Josh Vrieze, Product Manager, Vermeer Corporation

Mowing hay has come a long way since the days of the sickle mower. Sure, you might still see one used for small haying operations or for clipping pastures, but the industry really raised the bar with the invention of disc mowers. Today, disc mowers are the name of the game as they help producers cut hay at higher speeds, which is paramount when windows are tight.

The choice most producers make now isn’t between sickle mowers and disc mowers but between the two main types of disc mowers. Should you buy a 3-point mower or a trailed mower?

Each has advantages and disadvantages — so how do you decide which mower is right for your operation? As innovators in agricultural equipment for more than 70 years, the Vermeer team wants to offer their knowledge to help you decide.

A difference in design

A 3-point mower is named as such because it attaches to the rear three-point hitch of the tractor. All its weight is supported by the tractor, so when the tractor moves, the mower will follow close behind with little variation. A 3-point usually consists of a carrying frame, a pivoting gear box connection and the cutter bar — they are by no means light machines.

“You’ll generally need a larger tractor with a 3-point mower because of the weight,” said Eric Bergum, Vermeer Senior Design Engineer. “They’re also more restrictive in length because of the stability requirements. Usually eight pods or discs are about all you’ll see on a 3-point. I haven’t seen many longer than that.”

A trailed mower, in contrast, is towed by the tractor but carries itself by its own carriage system. This means less horsepower is needed from the tractor compared to a 3-point mower of the same size. With the ability to fold for easy transport, trailed mowers can really run the gamut in terms of size availability.

“We make everything from what we call an ��‘economy size’ trailed mower which would be like our TM600 all the way up to a TM1410 which is essentially a commercial, high-end operator-sized mower,” said Justin Olmstead, Vermeer Senior Project Engineer. “Depending on the model you choose, you can really knock out a lot of hay in a short amount of time.”

Compare and contrast

Bergum and Olmstead both agreed that most trailed mower models provide the extra features needed to mow in a bigger operation with more acres.

“The 3-point mower is more for ‘the weekender’ or the type of person that’s mowing fields and ditches — not a high amount of acres,” Bergum said. “It’s more for someone that’s not in a full-time hay business.”

With the ability to mow more acres faster, considerable advantages can be found with a trailed mower which often outshines the initial savings of a 3-point mower with a lower price tag. The reduced time and fuel consumption using one trailed mower, one tractor and one worker can pay off in the long run.

“One tractor, one TM1410 and one person can do as much work as two tractors, two M8040 3-point mowers and two people or even three M5040 3-point mowers, three tractors and three people,” Olmstead said. “There are always varying factors that can contribute, like the weather and field conditions, but generally speaking, a trailed mower is just going to get the job done more efficiently.”

Olmstead also pointed out that large trailed mowers can help prevent operator fatigue in the field when comparing to a small 3-point mower of half the size.

“At one level (trailed mowers) can also be considerably less fatiguing because you’re watching that cut edge less often,” Olmstead said. “With our larger trailed mowers, there are actually two separate cutter bars, so the TM1410 for example, has two, seven-disc cutter bars. Therefore, it’s almost like you’re pulling two 3-point mowers behind you, but they’re fixed in relation to each other, so you end up watching that overlap half as often.”

Bergum agrees, saying a trailed mower can offer a ground-hugging ability with independent overlapping cutter bars to help ensure clean cutting in the center.

“As far as cutting performance between the two, the independent cutter bars found on our Vermeer trailed mowers have a better ground contour to help navigate the field’s hidden obstacles,” Bergum said. “That’s probably one of the biggest differences. If you hit a rough patch in the field with a 3-point mower it won’t follow as well.”

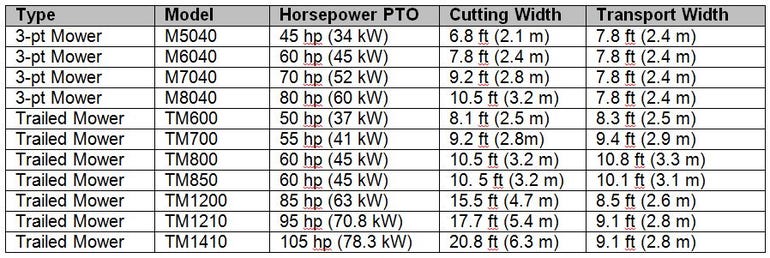

Vermeer trailed mowers and 3-point mowers comparison chart.

Maintenance tasks for each will be fairly similar, with a few exceptions for the differing designs.

“Your biggest maintenance worry is making sure you’re paying attention to the grease points and changing the cutting blades when they’re worn, but for the most part the ease of maintenance should be fairly evenly matched in both mower designs,” Bergum said. “The biggest difference being the trailed mower would have more greasing points and drive lines to monitor.”

There are two ways to go about choosing the mower that will work best for your situation: (1) Fit the mower to the size of your current tractor and determine how you will be using it. (2) Pencil out the cost and efficiency of different sizes and types of mowers based off your operations acres, size, labor and tractors to determine which might be best for you.

“A trailed mower can also be more flexible than a 3-point mower,” Bergum said. “It’s easier to go wider in length, easier to hook up and make adjustments, and it takes less horsepower to run. It just depends if you’re willing to spend the extra money upfront to get one.”

About the Author(s)

You May Also Like

.png?width=300&auto=webp&quality=80&disable=upscale)