Find breakeven price of corn silage

An Excel spreadsheet helps farmers determine the value of corn silage.

Two University of Missouri Extension specialists created a guide to help farmers take the guesswork out of the decision to harvest corn for grain or silage.

Frequently, corn harvested for silage was planted for harvest as a grain crop, says Joe Horner, an MU Extension agricultural business and policy specialist. He says these reasons may change because of tight livestock feed supplies, drought and other events that result in poor grain yield.

Horner and MU Extension economist Ray Massey released an updated Silage Cost Analyzer spreadsheet to help farmers estimate the breakeven price of corn silage. It is one tool that walks farmers through the process of determining whether it is best to harvest corn early for silage or wait for grain.

Silage is the harvest of whole corn plants at 60% to 70% whole plant moisture. Optimal harvest occurs when kernels are at half milk line to black layer.

The new spreadsheet provides farmers with options for pricing silage in the field, delivered to storage or delivered to the feed bunk.

Value of silage

Massey points out silage’s value per ton is 8 to 10 times the price of a bushel of corn. He says a factor of 8 to 9 times is used to price silage in the field, and a factor of 9 to 10 for pricing it in storage.

A higher factor is generally used for lower-priced corn and a lower factor for higher-priced corn. However, Massey warns farmers this rule needs to be reconsidered given current corn and input prices as silage priced in the field may be closer to seven times the price of a bushel of corn.

Another consideration is the dry matter percentage of silage. Most often, silage price is determined on wet basis or as it stands in the field.

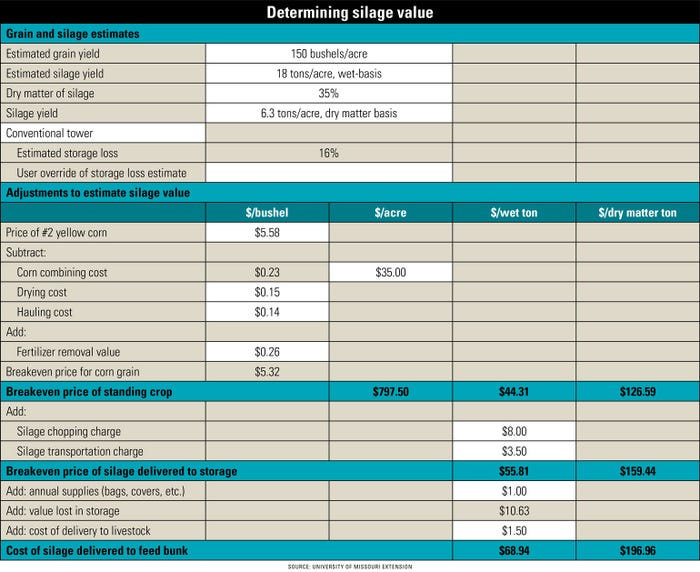

The Silage Cost Analyzer spreadsheet has the table below as an example. However, the interactive Excel file allows farmers to download it and place their own values into the table.

Costs related to silage

Farmers should realize that the “estimated storage loss” in the table above is a percentage determined by the storage structure. In this case, it is a conventional tower. The Silage Cost Analyzer spreadsheet offers loss percentages by storage structure on the sheet.

Producers should also consider costs of harvest, shrink, drying and transport. Livestock producers should weigh costs against the cost of other feedstuffs.

Silage harvest requires specialized equipment, including a chopper and wagons.

Then there is a nutrient cost. Corn harvested early is often not an easy choice as silage removes more nutrients — especially phosphorus and potassium — from the soil. If the soil becomes low on nutrients, farmers will need to replace them at an added expense.

Upside to silage

Planting corn for silage to deliberately remove nutrients also is an option in intensive manure-spreading areas and where the potential for nutrient runoff exists. Another consideration is the dry matter percentage of silage. Most often, price is determined on wet basis — as it stands in the field.

See “Pricing Corn Silage” and the Silage Cost Analyzer spreadsheet at extension.missouri.edu/g4591.

The University of Missouri Extension contributed to this article.

About the Author(s)

You May Also Like

.png?width=300&auto=webp&quality=80&disable=upscale)