U.S. Beef Exports Stymied By Lack Of 48-Hour Traceback

Individual cattle identification and tracking continues to elude the industry at the same time that the need for it continues to grow.

November 27, 2013

“Calves should not be part of a witness protection program. When the rest of the world and our competitors are identifying their animals, why can’t we?”

That was the question posed by a cattle feeder who was part of the strategy team — representing all industry sectors — that developed recommendations relative to the 2011 National Beef Quality Audit (NBQA). The results of the latest audit, heralded as the most comprehensive to date, were released last summer.

That audit identified the lack of knowing how and where cattle are raised as among the primary quality challenges for U.S. beef, just behind food safety and eating satisfaction. The NBQA also identified the scarcity of written protocols and recordkeeping as a key barrier to industry success.

Both require individual animal identification (ID) and the ability to track individual cattle as they move from sector to sector. That latter part seems only practically possible with the use of electronic ID (EID).

According to “Cattle Identification Practices on U.S. Beef Cow-Calf Operations,” a report from the National Animal Health Monitoring Service (NAHMS), 46.7% of operations surveyed applied at least one form of individual ID to calves, accounting for 64.8% of the calves. This information is derived from the most recent periodic NAHMS survey of cow-calf operations.

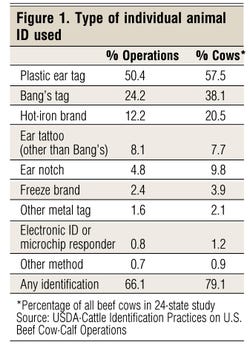

Among that same group, 66.1% of the operations used some form of individual ID on at least some of their cows, accounting for 79.1% of beef cows (see Figure 1).

Among that same group, 66.1% of the operations used some form of individual ID on at least some of their cows, accounting for 79.1% of beef cows (see Figure 1).

Plastic dangle tags were the most common form of ID (50.4% of operations and 57.5% of cows). EID was the least-common form of ID (0.8% of the operations and 1.2% of the cows).

For perspective, 38.1% of the cows on 24.2% of the operations were identified with brucellosis vaccination tags.

In a related NAHMS study, “Recordkeeping Practices on U.S. Beef Cow Operations,” 83.3% of cow-calf operations kept some form of records. Of those, 19.9% kept records with a computer (17%) on the operation, or away from the operation (2.9%).

At the feedlot level, 75.6% of feedlots with 1,000 head or more of capacity received at least some cattle with individual animal ID, accounting for 28.7% of the calves received. That comes from the NAHMS “Cattle Identification on U.S. Feedlots” study published in September.

The percentage of cattle tagged with individual ID at the feedlot (1,000-plus head) increased from 30.8% in 1999 to 45% in 2011. The percentage tagged with group/owner ID increased from 75.1% in 1999 to 85.5% in 2011.

Three barriers to EID progress

Plenty of folks once figured that by now, most every head of cattle in the marketing channel would boast an individual EID tag. They thought information tied to individual animal identity would flow between industry sectors, making the business more profitable while providing consumers with a more dependable eating experience.

“It all boils down to cost,” says Dale Blasi, a Kansas State University (KSU) Extension beef cow specialist. He also serves as director of KSU’s Animal Identification Knowledge Laboratory.

Illustration by Dennis Wolf

As an example, Blasi looks at the free “Estimating Costs of Radio Frequency Identifications Systems” calculator at beefstockerusa.org. You input component costs, including interest, for the system you have in mind, and then receive an annualized cost per head. An example page considers 250 cows with EID tags costing $2.25 each. Throw in a wand reader and other essentials, figure 6.5% interest, and you’re talking a cost of $7.21/head.

As cattle prices increase, EID costs less on a percentage basis, but it still represents an added cost.

Technology continues to challenge some, too. Blasi explains that low-frequency EID tags — currently the most common technology — are limited by the “read range.” If you want to scan the tag with a hand-held reader to retrieve the number, for all practical purposes, the cattle need to be in the chute or alley leading up to it.

Keep in mind that Blasi has likely put every ID technology and device brought to market within the last 12 years or so through its paces.

Ultra-high-frequency looks promising

Ultra-high-frequency (UHF) EID offers a much wider read range, and can capture every ID number from groups moving past a “read panel.” But, you have to figure out how to dial down the read range to scan that one single tag out of a bunch. In addition, Blasi says there are still unknowns surrounding high-frequency, including how environment affects technology performance.

“There could be a lot of interesting applications,” Blasi says. Adding other technologies to the mix, he mentions active tags — those that contain a battery — that can transmit information to a receiver constantly. Or, what about using a mobile phone and cloud technology rather than a computer to capture information transmitted from tags to readers?

Really, the potential uses are limited only by the imagination. “Think of tying ID technology to other technology like drones, and you could conceive of how the banking industry might be interested to monitor client inventory. Or how you could verify stocking rates to regulatory agencies,” Blasi says.

Arguably, adopters of EID technology so far have had to modify their existing systems to fit the technology, rather than plugging new technology into an existing system.

“There’s been some tweaking of the technology, but very little has changed,” Blasi says. “Without a definitive direction from government or the industry, a lot of ID technology companies have been in a holding pattern.”

Subscribe now to Cow-Calf Weekly to get the latest industry research and information in your inbox every Friday!

So far, there has been insufficient incentive for producers to modify how they do business in the name of ID, besides investing in the necessary equipment. But some producers certainly uncovered the incentive long ago. Between production efficiencies gained through individual animal management and increased marketing options, these folks say it more than pays for the equipment and the process. Of course, some of these same folks will almost apologize to visitors for noticing they spent money to put EID tags in their cows.

There’s no regulatory incentive, either. Compliance with the mandatory Animal Disease Traceability (ADT) program that began in March can be achieved with a metal clip tag.

Yet, the need for information tied to individual animal ID continues to grow. As the latest NBQA report points out, “The knowledge level of consumers is increasing, and they want to know more about how and where the animals were raised. Animal well-being is an attribute identified by retailers, foodservice and packers who want to ensure the animals have been raised humanely before harvest.”

The report goes on to say that, overall, the origin of cattle, how they were raised, and food safety are the categories “with significant odds of being identified by companies as ‘non-negotiable requirements’ prior to purchasing. Additionally, retailers mean what they say when they call a specific quality category a non-negotiable requirement, and are not influenced by a discounted price.”

You might also like:

States, Tribes Feeling Their Way Through Traceability Rule

65 Photos That Celebrate Cowgirls & Cattlewomen

3 Lessons From A Greenpeace Dropout

Year-End Analysis Shows Replacement Costs Are Surging

A Decade Later, U.S. Beef Industry No Closer To 48-Hour Traceback

About the Author(s)

You May Also Like